We specialize in the engineering and integration skills needed to provide complex manufacturing solutions for today's highly autonomous and information driven production environments.

As a provider of shop floor manufacturing software, we can understand how important it is for manufacturers to stay competitive in a fast-changing industry. Modern shop floor software helps you streamline your production, save time, and use your resources wisely. Whether you run a small shop or a large factory, using the latest shop floor manufacturing software can make a big difference. Let us explain how.

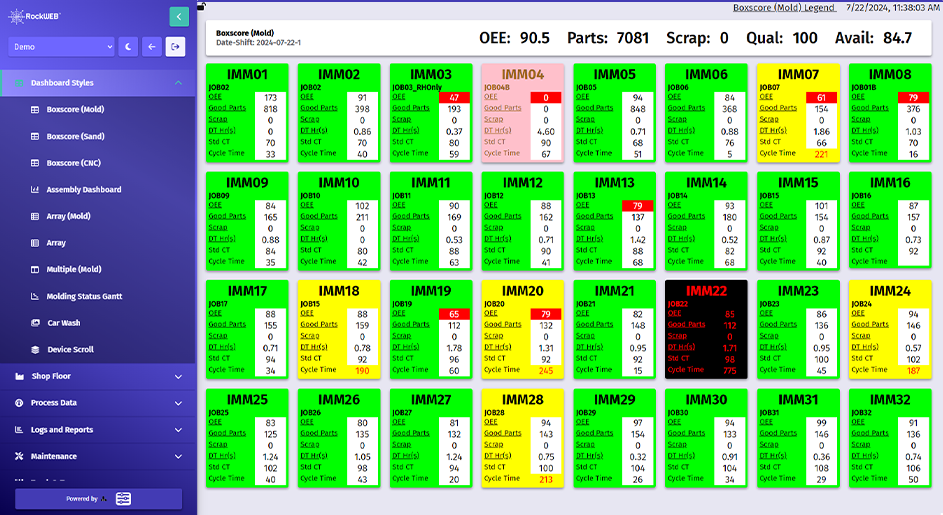

This software is a tool that helps you track and manage everything that happens on the factory floor. It gives you real-time data on production, machine performance, inventory, and quality control. With all this information in one place, you can make better decisions, solve issues faster, and keep things running smoothly.

Why Staying Competitive Matters

In manufacturing, staying competitive means producing high-quality products efficiently and at the lowest cost possible. Customers expect fast deliveries, consistent quality, and reasonable prices. With the latest shop floor software, you can meet these expectations by improving productivity, managing resources better, and reducing waste.

How Shop Floor Manufacturing Software Helps You Compete

Here are some of the main ways this software can keep your business competitive:

- Real-Time Production Tracking

With our shop floor software, you can monitor production in real-time. If there's an issue with a machine or a delay in the process, you'll know right away. This means you can fix problems quickly and avoid costly downtime. When you know exactly what's happening on the floor, you can make better decisions and keep production on schedule. - Better Quality Control

High quality is essential for keeping customers happy. Our Shop floor software helps track quality at each step of production. It collects data on each product, making it easy to spot any quality issues early on. By catching problems right away, you reduce waste and make sure every product meets your standards. - Efficient Inventory Management

Managing inventory is another area where shop floor software can help. It tracks all materials, parts, and products in real time. This prevents overstocking or running out of materials, both of which can slow down production and increase costs. With accurate inventory data, you always know what you have on hand and when to reorder supplies. - Improved Scheduling and Workforce Management

The latest shop floor software also helps with scheduling tasks and managing labor. It assigns tasks based on production needs and tracks worker hours and productivity. This ensures that all resources—both machines and people—are being used efficiently, which leads to faster production times and lower costs.

Get Ahead with Advanced Technology

Using the latest shop floor software keeps your factory up-to-date with industry standards. It also makes it easier to scale as your business grows. By relying on data and automating many tasks, you're able to focus more on improving processes and less on handling everyday problems.

Final words

By investing in advanced Shop Floor Software, you're investing in the future of your business. If you're interested in learning more about how this software can help you stay competitive, reach out to us at Rockware Corp. We're here to help you make the most of your production!