We specialize in the engineering and integration skills needed to provide complex manufacturing solutions for today's highly autonomous and information driven production environments.

At our industrial software company, we often talk about how important it is for businesses to keep their assembly lines running smoothly. An assembly line is where products are put together, and keeping it efficient can make a big difference in how fast and well things are made. That's where our manufacturing assembly software comes in. Let us explain how our software helps make assembly lines work better and faster.

What is Manufacturing Assembly Software?

Manufacturing assembly software is a tool that helps manage and improve the assembly process. Think of it as a digital helper that keeps track of all the moving parts in an assembly line. It helps organize tasks, monitor progress, and make sure everything runs as smoothly as possible.

How Does Our Software Help?

Organizes Tasks Clearly: One of the main ways our software helps is by organizing tasks clearly. It breaks down the assembly process into smaller, easy-to-manage steps. Each step is assigned to the right worker or machine. This organization helps everyone know exactly what they need to do and when, which reduces confusion and mistakes.

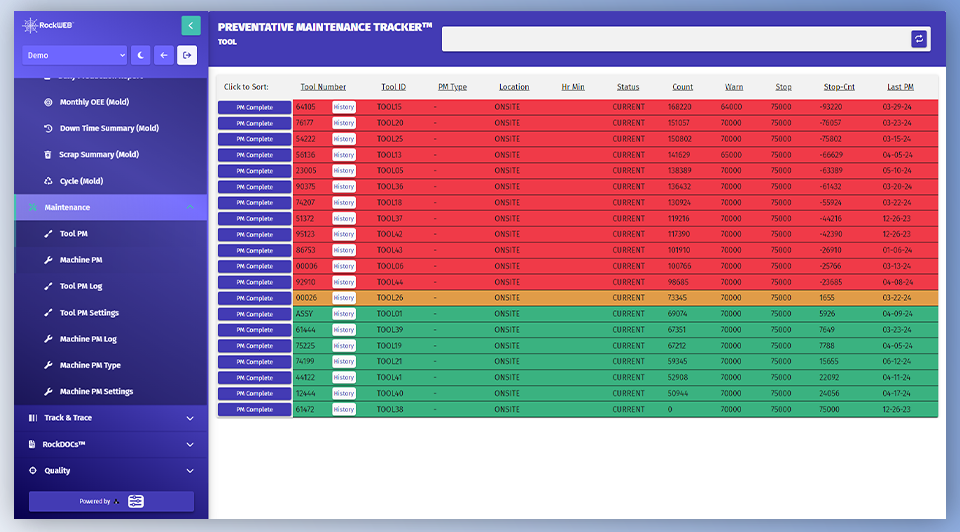

Monitors Progress in Real-Time: Our software lets you see what's happening on the assembly line right now. You can check how many items are being made, if there are any delays, and if everything is running as planned. This real-time view helps you catch and fix problems quickly before they become bigger issues.

Identifies and Fixes Bottlenecks: Sometimes, parts of the assembly line slow down or get stuck, which we call bottlenecks. Our software helps identify these bottlenecks by tracking where the process is slowing down. Once we know where the problem is, we can make changes to speed things up and keep production moving smoothly.

Automates Repetitive Tasks: Many tasks on an assembly line are repetitive and can be time-consuming. Our software helps automate these repetitive tasks, which speeds up the process and reduces the chances of human errors. Automation helps the assembly line work faster and lets workers focus on more complex tasks.

Improves Communication: Good communication is crucial for a smooth assembly line. Our software helps by providing a central place for sharing updates and information. Everyone involved can see the current status of the assembly line and stay informed about any changes or issues. This makes teamwork easier and more effective.

Tracks Performance and Progress: Our software keeps track of how well the assembly line is performing. It collects data on things like how many items are made and how long each task takes. By looking at this information, you can find areas that need improvement and make adjustments to increase efficiency.

Our Manufacturing MES (Manufacturing Execution System) software is a digital tool that manages and monitors production processes in real-time. It helps streamline operations by coordinating tasks, tracking performance, and ensuring quality control on the shop floor.

Manages Resources Effectively: Managing resources like materials and equipment is important for keeping the assembly line running smoothly. Our software helps keep track of these resources, ensuring that everything is used efficiently and nothing is wasted. This helps keep costs down and production on schedule.

Closing opinions

In summary, our manufacturing assembly software is a valuable tool for making assembly lines more efficient. If you want to keep your assembly line running smoothly and speed up production, our software is a great solution. It helps everything run better so you can focus on delivering high-quality products to your customers. Contact us today at Rockware Corp for more information in this regard!