We specialize in the engineering and integration skills needed to provide complex manufacturing solutions for today's highly autonomous and information driven production environments.

At our industrial software company, we often talk to clients about the importance of using the right tools for their manufacturing needs. One tool that we find incredibly valuable, especially for those involved in creating plastic parts, is Injection Molding software Systems. If you're not familiar with it, you might wonder why it's such a big deal. Let us break it down for you in simple terms.

What is Injection Molding Software?

First off, let's talk about what injection molding software is. This type of software helps companies manage and control the injection molding process, where plastic is melted and injected into molds to create various parts. The software provides a way to design molds, set up machines, monitor production, and ensure that each part meets quality standards.

Why is Injection Molding Software Necessary?

Efficiency: One of the biggest reasons to use injection molding software is to improve efficiency. The software helps streamline the entire process, from designing the mold to setting the machine and running the production. By automating and managing these steps, the software helps make sure everything runs smoothly and quickly. This means you can produce more parts in less time, which is crucial for meeting tight deadlines and high demand.

Accuracy and Consistency: Injection molding software helps ensure that each part produced is exactly the same as the others. The software controls the machine settings and monitors the process to make sure everything is done correctly. This level of accuracy is important because even small differences in parts can cause big problems, especially if the parts need to fit together or work in a specific way. Consistent quality helps prevent defects and reduces the need for rework.

Cost Savings: Using injection molding software can save money in the long run. By optimizing the process, the software helps reduce waste and avoid costly errors. For instance, it can identify the most efficient way to use materials and minimize leftover scrap. It also helps prevent machine breakdowns by monitoring the equipment and catching potential issues before they become serious problems.

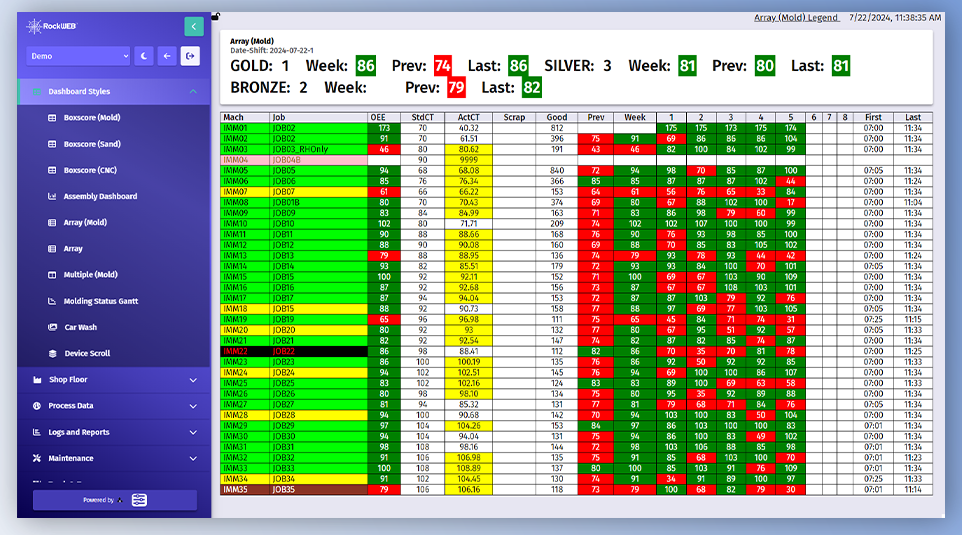

Real-Time Monitoring: The software allows you to monitor the production process in real time. You can see how the machines are running, track the progress of each part, and make adjustments if needed. This helps catch any issues early on, so you can fix them before they affect a large number of parts. Real-time monitoring also helps you maintain control over production schedules and ensures that everything stays on track.

Improved Design and Testing: With injection molding software, you can design and test molds more effectively. The software lets you create detailed designs and run simulations to see how the parts will turn out. This helps you identify any potential problems before you start making the actual molds, which can save time and reduce the risk of costly mistakes.

Closing words

In summary, Injection Molding software Systems are essential for anyone involved in the injection molding process. At our industrial software company, we believe that using the right software can make a huge difference in the quality and success of your manufacturing operations.

If you're looking to streamline your injection molding operations and ensure high-quality production, investing in injection molding software from a reliable company like us Rockware Corp is a smart move. Our advanced software solutions ensure efficiency, accuracy, and cost savings, helping you optimize your manufacturing process. Contact us today for detailed information regarding this!